Pipa Baja Karbon Dilas Spiral Pikeun Pipa Cai Bawah Tanah

Jaringan cai taneuh mangrupikeun bagian penting tina infrastruktur kota atanapi kota leutik mana waé. Jaringan ieu tanggung jawab pikeun nyayogikeun cai nginum anu bersih sareng aman ka bumi, bisnis, sareng lembaga sanésna. Tanpa sistem pipa anu tiasa dipercaya, aksés kana cai bersih bakal kaganggu pisan, anu nyababkeun poténsi résiko kaséhatan sareng gangguan kana kahirupan sapopoe. Ku alatan éta, penting pisan pikeun mastikeun yén bahan anu dianggo dina pipa ieu kualitasna luhur sareng sanggup nyumponan sarat pikeun transportasi cai taneuh.

| Diaméter Luar Anu Ditangtukeun (D) | Kandel Tembok anu Ditangtukeun dina mm | Tekanan uji minimum (Mpa) | ||||||||||

| Kelas Baja | ||||||||||||

| in | mm | L210(A) | L245(B) | L290(X42) | L320(X46) | L360(X52) | L390(X56) | L415(X60) | L450(X65) | L485(X70) | L555(X80) | |

| 8-5/8 | 219.1 | 5.0 | 5.8 | 6.7 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 |

| 7.0 | 8.1 | 9.4 | 13.9 | 15.3 | 17.3 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 11.5 | 13.4 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 9-5/8 | 244.5 | 5.0 | 5.2 | 6.0 | 10.1 | 11.1 | 12.5 | 13.6 | 14.4 | 15.6 | 16.9 | 19.3 |

| 7.0 | 7.2 | 8.4 | 14.1 | 15.6 | 17.5 | 19.0 | 20.2 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 10.3 | 12.0 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 10-3/4 | 273.1 | 5.0 | 4.6 | 5.4 | 9.0 | 10.1 | 11.2 | 12.1 | 12.9 | 14.0 | 15.1 | 17.3 |

| 7.0 | 6.5 | 7.5 | 12.6 | 13.9 | 15.7 | 17.0 | 18.1 | 19.6 | 20.7 | 20.7 | ||

| 10.0 | 9.2 | 10.8 | 18.1 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 12-3/4 | 323.9 | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.6 |

| 7.0 | 5.5 | 6.5 | 10.7 | 11.8 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.4 | ||

| 10.0 | 7.8 | 9.1 | 15.2 | 16.8 | 18.9 | 20.5 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (325.0) | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.5 | |

| 7.0 | 5.4 | 6.3 | 10.6 | 11.7 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.3 | ||

| 10.0 | 7.8 | 9.0 | 15.2 | 16.7 | 18.8 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 13-3/8 | 339.7 | 5.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.1 | 13.9 |

| 8.0 | 5.9 | 6.9 | 11.6 | 12.8 | 14.4 | 15.6 | 16.6 | 18.0 | 19.4 | 20.7 | ||

| 12.0 | 8.9 | 10.4 | 17.4 | 19.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 14 | 355.6 | 6.0 | 4.3 | 5.0 | 8.3 | 9.2 | 10.3 | 11.2 | 11.9 | 12.9 | 13.9 | 15.9 |

| 8.0 | 5.7 | 6.6 | 11.1 | 12.2 | 13.8 | 14.9 | 15.9 | 17.2 | 18.6 | 20.7 | ||

| 12.0 | 8.5 | 9.9 | 16.6 | 18.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (377.0) | 6.0 | 4.0 | 4.7 | 7.8 | 8.6 | 9.7 | 10.6 | 11.2 | 12.2 | 13.1 | 15.0 | |

| 8.0 | 5.3 | 6.2 | 10.5 | 11.5 | 13.0 | 14.1 | 15.0 | 16.2 | 17.5 | 20.0 | ||

| 12.0 | 8.0 | 9.4 | 15.7 | 17.3 | 19.5 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 16 | 406.4 | 6.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.2 | 13.9 |

| 8.0 | 5.0 | 5.8 | 9.7 | 10.7 | 12.0 | 13.1 | 13.9 | 15.1 | 16.2 | 18.6 | ||

| 12.0 | 7.4 | 8.7 | 14.6 | 16.1 | 18.1 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (426.0) | 6.0 | 3.5 | 4.1 | 6.9 | 7.7 | 8.6 | 9.3 | 9.9 | 10.8 | 11.6 | 13.3 | |

| 8.0 | 4.7 | 5.5 | 9.3 | 10.2 | 11.5 | 12.5 | 13.2 | 14.4 | 15.5 | 17.7 | ||

| 12.0 | 7.1 | 8.3 | 13.9 | 15.3 | 17.2 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 18 | 457.0 | 6.0 | 3.3 | 3.9 | 6.5 | 7.1 | 8.0 | 8.7 | 9.3 | 10.0 | 10.8 | 12.4 |

| 8.0 | 4.4 | 5.1 | 8.6 | 9.5 | 10.7 | 11.6 | 12.4 | 13.4 | 14.4 | 16.5 | ||

| 12.0 | 6.6 | 7.7 | 12.9 | 14.3 | 16.1 | 17.4 | 18.5 | 20.1 | 20.7 | 20.7 | ||

| 20 | 508.0 | 6.0 | 3.0 | 3.5 | 6.2 | 6.8 | 7.7 | 8.3 | 8.8 | 9.6 | 10.3 | 11.8 |

| 8.0 | 4.0 | 4.6 | 8.2 | 9.1 | 10.2 | 11.1 | 11.8 | 12.8 | 13.7 | 15.7 | ||

| 12.0 | 6.0 | 6.9 | 12.3 | 13.6 | 15.3 | 16.6 | 17.6 | 19.1 | 20.6 | 20.7 | ||

| 16.0 | 7.9 | 9.3 | 16.4 | 18.1 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (529.0) | 6.0 | 2.9 | 3.3 | 5.9 | 6.5 | 7.3 | 8.0 | 8.5 | 9.2 | 9.9 | 11.3 | |

| 9.0 | 4.3 | 5.0 | 8.9 | 9.8 | 11.0 | 11.9 | 12.7 | 13.8 | 14.9 | 17.0 | ||

| 12.0 | 5.7 | 6.7 | 11.8 | 13.1 | 14.7 | 15.9 | 16.9 | 18.4 | 19.8 | 20.7 | ||

| 14.0 | 6.7 | 7.8 | 13.8 | 15.2 | 17.1 | 18.6 | 19.8 | 20.7 | 20.7 | 20.7 | ||

| 16.0 | 7.6 | 8.9 | 15.8 | 17.4 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22 | 559.0 | 6.0 | 2.7 | 3.2 | 5.6 | 6.2 | 7.0 | 7.5 | 8.0 | 8.7 | 9.4 | 10.7 |

| 9.0 | 4.1 | 4.7 | 8.4 | 9.3 | 10.4 | 11.3 | 12.0 | 13.0 | 14.1 | 16.1 | ||

| 12.0 | 5.4 | 6.3 | 11.2 | 12.4 | 13.9 | 15.1 | 16.0 | 17.4 | 18.7 | 20.7 | ||

| 14.0 | 6.3 | 7.4 | 13.1 | 14.4 | 16.2 | 17.6 | 18.7 | 20.3 | 20.7 | 20.7 | ||

| 19.1 | 8.6 | 10.0 | 17.8 | 19.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22.2 | 10.0 | 11.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 24 | 610.0 | 6.0 | 2.5 | 2.9 | 5.1 | 5.7 | 6.4 | 6.9 | 7.3 | 8.0 | 8.6 | 9.8 |

| 9.0 | 3.7 | 4.3 | 7.7 | 8.5 | 9.6 | 10.4 | 11.0 | 12.0 | 12.9 | 14.7 | ||

| 12.0 | 5.0 | 5.8 | 10.3 | 11.3 | 12.7 | 13.8 | 14.7 | 15.9 | 17.2 | 19.7 | ||

| 14.0 | 5.8 | 6.8 | 12.0 | 13.2 | 14.9 | 16.1 | 17.1 | 18.6 | 20.0 | 20.7 | ||

| 19.1 | 7.9 | 9.1 | 16.3 | 17.9 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.5 | 12.0 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (630.0) | 6.0 | 2.4 | 2.8 | 5.0 | 5.5 | 6.2 | 6.7 | 7.1 | 7.7 | 8.3 | 9.5 | |

| 9.0 | 3.6 | 4.2 | 7.5 | 8.2 | 9.3 | 10.0 | 10.7 | 11.6 | 12.5 | 14.3 | ||

| 12.0 | 4.8 | 5.6 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 | ||

| 16.0 | 6.4 | 7.5 | 13.3 | 14.6 | 16.5 | 17.8 | 19.0 | 20.6 | 20.7 | 20.7 | ||

| 19.1 | 7.6 | 8.9 | 15.8 | 17.5 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.2 | 11.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

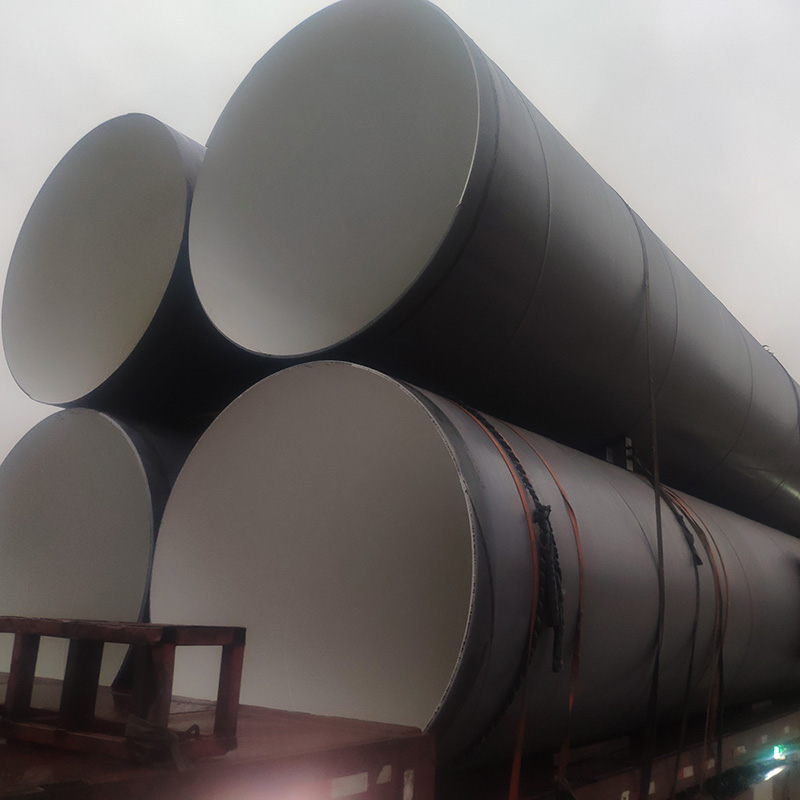

Pipa baja karbon anu dilas spiral, sapertos S235 JR sarengPipa jalur SSAW X70, mangrupikeun pilihan anu populér pikeun pipa cai handapeun taneuh kusabab daya tahan sareng tahan korosi anu saé. Pipa-pipa ieu didamel nganggo prosés las spiral, pikeun mastikeun struktur anu kuat sareng mampuh nahan tekanan sareng faktor lingkungan anu aya hubunganana sareng transportasi cai taneuh. Salaku tambahan, pipa-pipa ieu didamel tina baja karbon kualitas luhur pikeun kakuatan sareng umur panjang anu unggul, jantenkeun pilihan anu tiasa dipercaya pikeun sistem distribusi cai jangka panjang.

Salah sahiji kaunggulan utama tina ngagunakeunpipa baja karbon anu dilas spiralpikeun transportasi cai taneuh nyaéta résistansi korosi anu luhur. Pipa handapeun taneuh terus-terusan kakeunaan kalembaban sareng faktor lingkungan sanésna, anu tiasa nyababkeun bahan tradisional sapertos beton atanapi PVC karat sareng buruk. Nanging, pipa baja karbon tahan pisan kana korosi, mastikeun aranjeunna ngajaga integritas strukturalna kana waktosna. Résistansi korosi ieu sacara signifikan ngirangan kabutuhan pangropéa sareng panggantian, pamustunganana ngahémat biaya sistem cai.

Salian ti éta, kakuatan sareng daya tahan pipa baja karbon anu dilas spiral ngajantenkeun idéal pikeun pamasangan handapeun taneuh. Pipa-pipa ieu tiasa nahan tekanan éksternal tina taneuh sareng unsur handapeun taneuh anu sanés, mastikeun yén éta tetep utuh sareng tiasa dianggo sapanjang umur jasana. Salian ti éta, konstruksi sareng permukaan interior anu mulus ngaminimalkeun résiko panyumbatan atanapi bocor, langkung ningkatkeun reliabilitas sareng efisiensi transportasi cai taneuh.

Ringkesanana,pipa cai handapeun taneuhmangrupa bagian penting tina infrastruktur modéren, sareng pilihan bahan anu dianggo dina pipa ieu penting pisan pikeun kinerja sareng umur panjangna. Pipa baja karbon anu dilas spiral, sapertos pipa jalur S235 JR sareng X70 SSAW, nawiskeun seueur kaunggulan pikeun transportasi cai taneuh, kalebet daya tahan anu unggul, tahan korosi sareng kakuatan anu luhur. Ku cara ngamangpaatkeun pipa kualitas luhur ieu, sistem cai tiasa mastikeun pangiriman cai anu tiasa dipercaya sareng efisien ka masarakat bari ngaminimalkeun kabutuhan pangropéa sareng panggantian.